CALL US TODAY!

SUSTAINABILITY

Our Commitment to Sustainability

A founding principle at Graphitti Sign & Graphic Studio, is production of marketing and graphic wall covering products in a socially and environmentally responsible manner.

Some examples of our commitment to that founding principal follow:

At Graphitti Sign & Graphic Studio, we use no environmentally harmful solvent ink process as do many sign and graphics producers. For direct to substrate work, our flatbed printer is a UV machine. Since UV inks dry immediately and release no VOC's into the environment, UV printing is considered a green technology, safer for the environment and leaving an almost zero carbon footprint. For roll to roll media, we incorporate the green technology of the HP Latex 360 printer with superior latex water-based inks.

The vast majority of wide format printing in signage, uses solvent ink-based printers. Studios utilizing solvent-based printers often experience a level of fumes and odors creating health concerns. Complaints include headaches, dry mouth, and sinus trouble, sometimes to the point of needing medical intervention. The fumes pose real health concerns.

With solvent-based ink print, a solvent mixes with the ink, carries ink to the media and is printed on the media. When the ink drop lands on the media, it chemically softens and dissolves the surface, and the pigment or resin is absorbed into the media. The solvent evaporates, leaving the pigment/resin inside the media to produce a print. This is where the problems begin.

The evaporated solvent product has been deemed hazardous to people at high-concentration levels. The fumes and odors you smell from your print or wall covering are called “hazardous indoor vapors.” These vapors are regulated in the U.S. by OSHA. Many of the chemicals used have exposure limits set as low as 20 parts per million (ppm). Printed media produced with solvent based ink, must be allowed to “outgas” (typically 24 hours) before laminating. Unfortunately, outgassing continues after the product is completed and installed. Manufacturers have been able to pass responsibility regarding hazardous indoor vapor exposure to end users. This unfortunately doesn’t help end users establish what may or may not be needed to provide a clean and healthy working environment.

In addition to yielding superior color management, our state of the art HP Latex 360 Printer utilizes water based, odorless Latex ink which does not cause health problems or produce hazardous waste. The HP Latex 360 Printer is GREENGARD & UL certified and requires no ventilation. Products do not require “off gassing” prior to finishing or installation which helps us meet your schedule. The HP L360 is Energy Star efficient. The printer meets the lowest pint emission standards and does not produce hazardous air pollutants (HAPs). The HP L360 uses GREENGUARD GOLD Certified inks & prints meeting AgBB criteria.

The HP Latex 360 Printer is a healthier approach to signage or graphic wall covering printing with advantages from the work zone to the point-of-display of finished prints.

HP Latex Inks advantages over solvent-based inks:

- No special ventilation required

- HP Latex Inks are non-flammable and non-combustible, nickel free

- No hazard warning labels or Hazardous Air Pollutants (HAPs)

- HP Latex Ink prints are odorless, allowing placement in sensitive environments from such as: healthcare; restaurants; schools; daycares; office environments; retail spaces.

HP Latex Printing Technologies provide many opportunities to reduce and recycle. For example:

- ENERGY STAR® qualified printers meet strict energy efficiency guidelines without sacrificing performance

- EPEAT registered printers, according to a comprehensive environmental rating that helps identify “greener” computers and other electronic equipment6

- No special power requirements

- All ink cartridges, printheads, and maintenance supplies are recyclable

- Each printer contains more than 85% recyclable/reusable content by weight HP is the only large format digital printing manufacturer to earn UL ECOLOGO® Certification8 for latex printing.

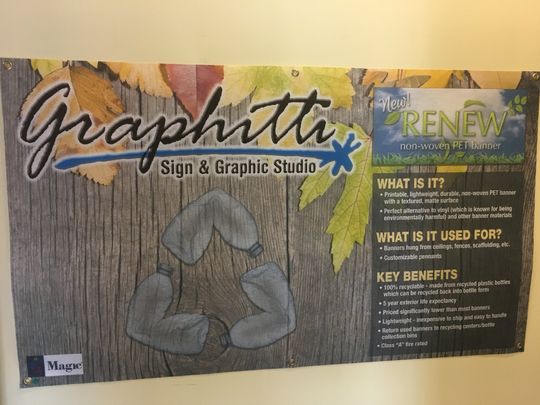

In addition to printing only with HP latex inks, we offer a variety of environmentally sound media options.

We can produce using non-vinyl media that are recyclable and low VOC for a wide range of applications.

Prints produced with HP Latex Inks on HP PVC-free Wall Paper media:

- Are GREENGUARD GOLD Certified to standards for low chemical emissions into indoor air

- Meet AgBB criteria for health-related evaluation of VOC emissions of indoor building products

- Are rated A+ per Émissions dans l’air intérieur on the level of emission of volatile substances in indoor air

Posing health risks if inhaled

- Meet the Oeko-Tex® Standard 100 criteria, for products tested and certified from a human health perspective

In addition, HP PVC-free Wall Paper:

- Is FSC® certified, carrying the Forest Stewardship Council (FSC) Mix label, and signifying that this media supports the development of responsible forest management worldwide.

- FSC®-certified wall decorations can help building owners obtain US LEED credits.

At Graphitti Sign & Graphic Studio, We are committed to helping our customers recycle responsibly

In our day to day work in our studio, waste materials not subject to a manufacturers or suppliers formal recycle program, are sorted by type and delivered to Williamson County Recycling centers for processing.

More than 75% of our HP ink cartridges and 24% of HP LaserJet toner cartridges are manufactured with “closed loop” recycled plastic. HP has over 3,700 recycling drop off locations in the U.S. and provides free recycling of equipment through a partnership with Staples.

We participate in HP Planet Partners recycling programs for materials such as:

- Ink and LaserJet cartridges

- Hardware

- Large-format Media

- Batteries from notebooks and smartphones

- Product Packaging

Graphitti Sign & Graphic Studio biophilia discussion:

CONTACT INFORMATION

Phone: (615) 656-8420

Email: info@graphittisigns.com

Sales Office: 3401 Malory Lane, Suite 100, Franklin TN 37067

Hours of Operation:

- Mon - Fri

- -

- Saturday

- Appointment Only

- Sunday

- Closed

OUR LOCATION

Content, including images, displayed on this website is protected by copyright laws. Downloading, republication, retransmission or reproduction of content on this website is strictly prohibited. Terms of Use

| Privacy Policy